Is Your Workbench Working Against You?

You’ve invested in quality equipment, streamlined your workflows, and hired skilled technicians. But something’s still off, productivity dips, workers complain of discomfort, and output isn’t quite where it should be.

Could the real problem be the workbench itself?

In modern manufacturing, the ergonomic design of workstations and workbenches is no longer optional, it’s essential.

In modern manufacturing, especially in sectors like electronics, textiles, automotive, aerospace, pharmaceuticals, heavy engineering, medical device manufacturing, defense, precision tooling, and assembly line production, the ergonomic design of workstations and workbenches is no longer optional, it’s essential. From R&D workbenches and technical workstations to ESD-safe benches, modular workbenches and height-adjustable tables, every workspace should be designed to support human physical needs, not the other way around.

In modern manufacturing, the ergonomic design of workstations and workbenches is no longer optional, it’s essential.

Industries where it matters:

Electronics, Textiles, Automotive, Aerospace, Pharmaceuticals, Heavy Engineering, Medical Devices, Defense, and Tooling.

Why It Matters:

Every workspace should be designed to support human physical needs- not the other way around.

Ergonomics Is Essential For:

“A poorly designed workstation can reduce productivity by up to 30% and increase injury risk.”

— Occupational Health & Safety Journal

What Is an Ergonomic Workbench and Why Does It Matter?

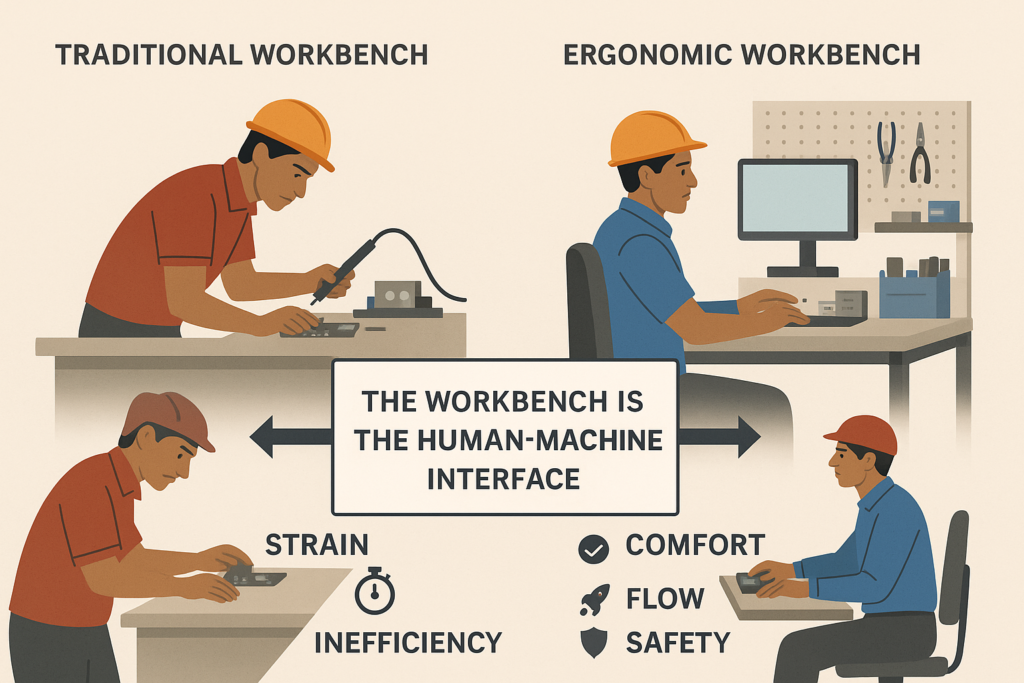

At its core, ergonomics is the science of designing tools, tasks, and environments that suit the user’s physical and cognitive abilities. When applied to manufacturing environments, this translates to an ergonomic workbench that minimizes strain, optimizes posture, and enables safer, more efficient workflows.

The Cost of Poor Ergonomics in Workstations

If a workstation is too high, too deep, lacks foot support, or demands awkward reaches- your workforce pays the price first, and your business follows:

- Repetitive strain injuries (RSIs)

- Lower productivity due to fatigue

- Increased absenteeism

- Frequent tool misplacement

- Wasted movement and inefficient task flows

Beyond the human toll, the cost of poor ergonomics in manufacturing workspaces can include:

- Higher medical claims

- Increased worker compensation payouts

- Loss of skilled labor due to dissatisfaction

- Disruption in production timelines

Advantages of Using an Ergonomic Workbench in Manufacturing

1. Improved Worker Comfort & Safety

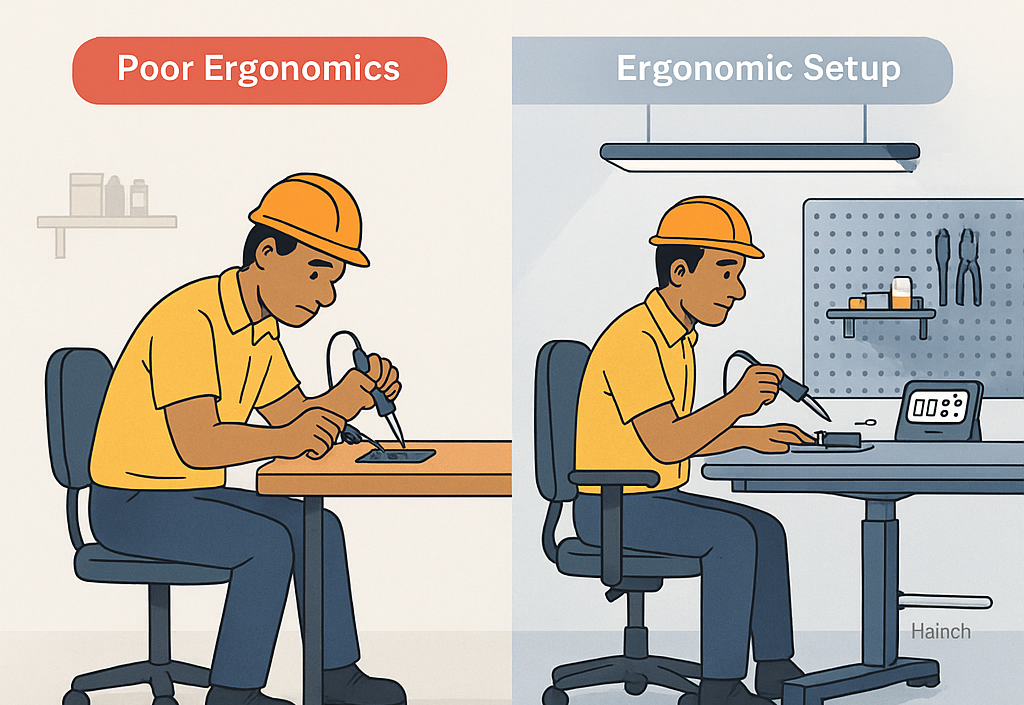

In roles that demand precision- like soldering, inspection, or R&D testing- worker posture directly impacts performance and health. Ergonomic workbenches with adjustable height, footrests, and user-centric layouts help reduce physical strain and repetitive stress. By supporting both seated and standing positions, they allow workers to shift naturally throughout the day, lowering the risk of fatigue, back pain, and long-term injuries like musculoskeletal disorders (MSDs).

“Musculoskeletal disorders account for nearly 30% of all workplace injuries.”

— National Institute for Occupational Safety and Health (NIOSH)

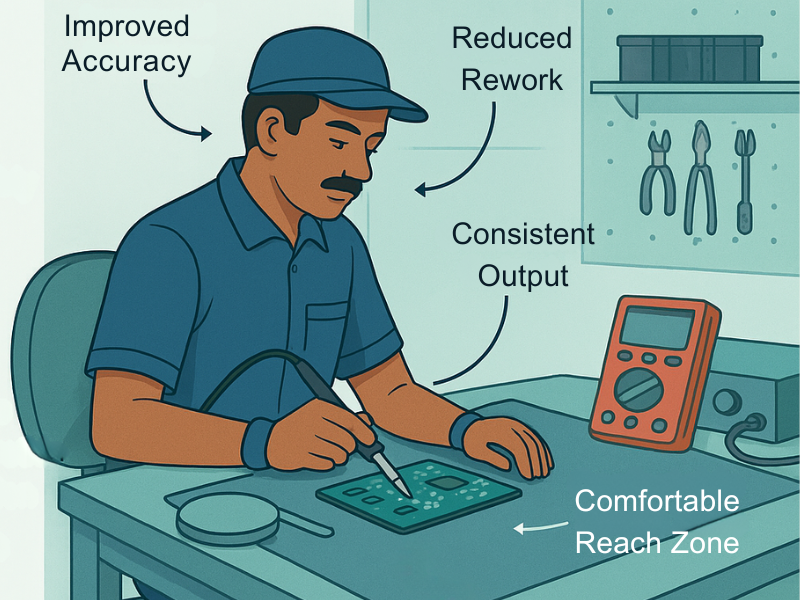

2. Better Product Quality

A well-organized, ergonomic technical workstation ensures tools, materials, and instruments are always within a comfortable reach. This allows for more focused, accurate, and consistent handling of components- especially in quality-sensitive tasks like PCB testing, component assembly, or calibration. Less strain and fewer distractions often lead to fewer errors, improved consistency, and reduced rework or scrap- making every output count.

“Musculoskeletal disorders account for nearly 30% of all workplace injuries.”

— National Institute for Occupational Safety and Health (NIOSH)

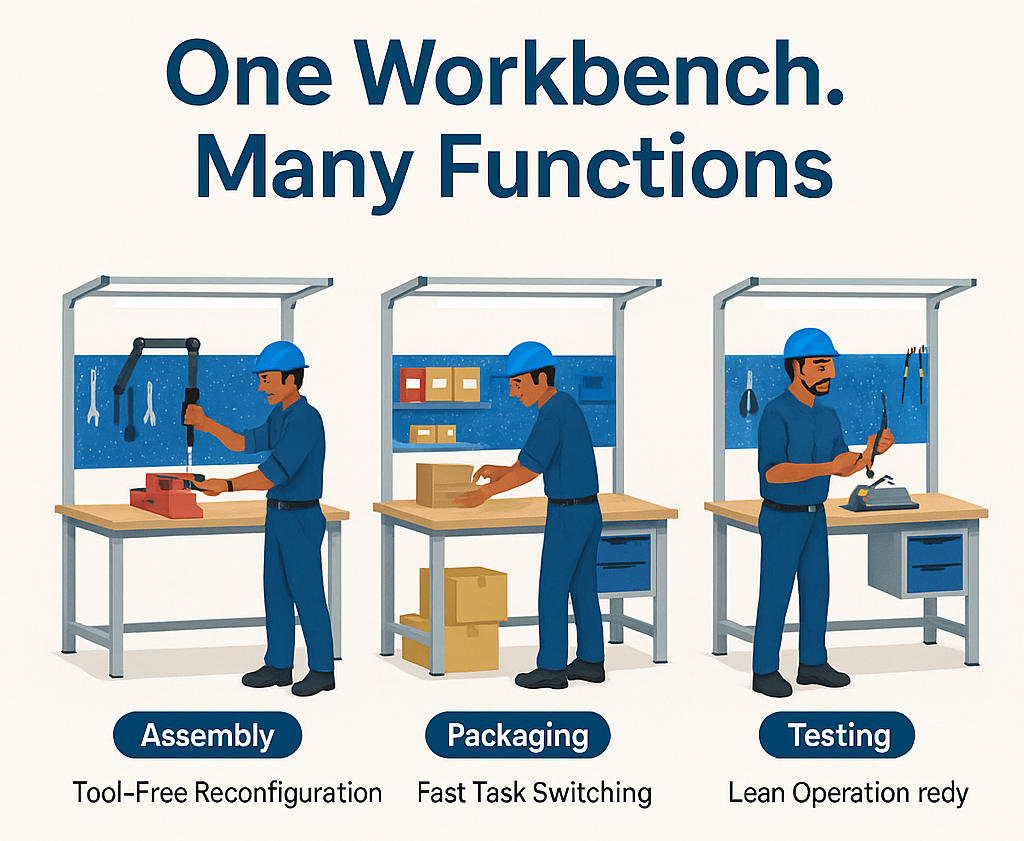

3. Flexibility & Adaptability

Modern operations- from oil & gas labs to electronic assembly lines- need agile setups. Modular workbenches offer unmatched flexibility by allowing users to quickly reconfigure their workspace. Need to switch from assembly to packaging? Simply detach tools like torque arms or vices and attach label holders or shelf dividers. This saves time, reduces clutter, and eliminates the need for multiple benches for different tasks- perfect for lean and fast-changing environments.

“Musculoskeletal disorders account for nearly 30% of all workplace injuries.”

— National Institute for Occupational Safety and Health (NIOSH)

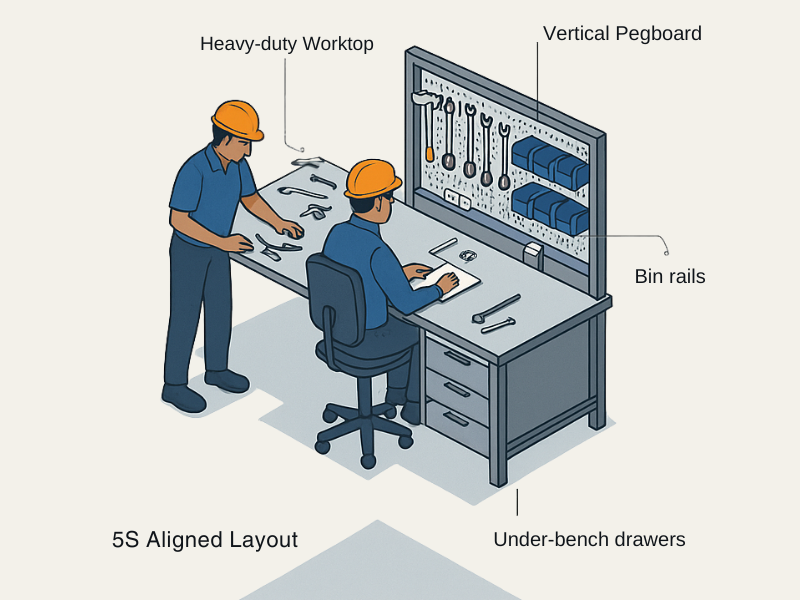

4. Space Optimization

In manufacturing and R&D environments where floor space is always at a premium, ergonomic modular workstations help maximize efficiency. With integrated accessories like vertical pegboards, under-bench drawers, bin strips, and power rails, every tool has its place- freeing up work surfaces and walkways. This leads to a cleaner, more organized, and 5S-aligned workspace that improves productivity without expanding the footprint.

“Musculoskeletal disorders account for nearly 30% of all workplace injuries.”

— National Institute for Occupational Safety and Health (NIOSH)

5. Compliance with Occupational Standards

Companies must meet global standards to ensure safety and operational reliability. Ergonomically designed workstations help businesses align with OSHA (Occupational Safety and Health Administration) and ISO ergonomics guidelines. By proactively addressing workstation design, posture, and fatigue prevention, you reduce the risk of workplace injuries and strengthen your compliance posture- minimizing potential liabilities or audit issues.

“Musculoskeletal disorders account for nearly 30% of all workplace injuries.”

— National Institute for Occupational Safety and Health (NIOSH)

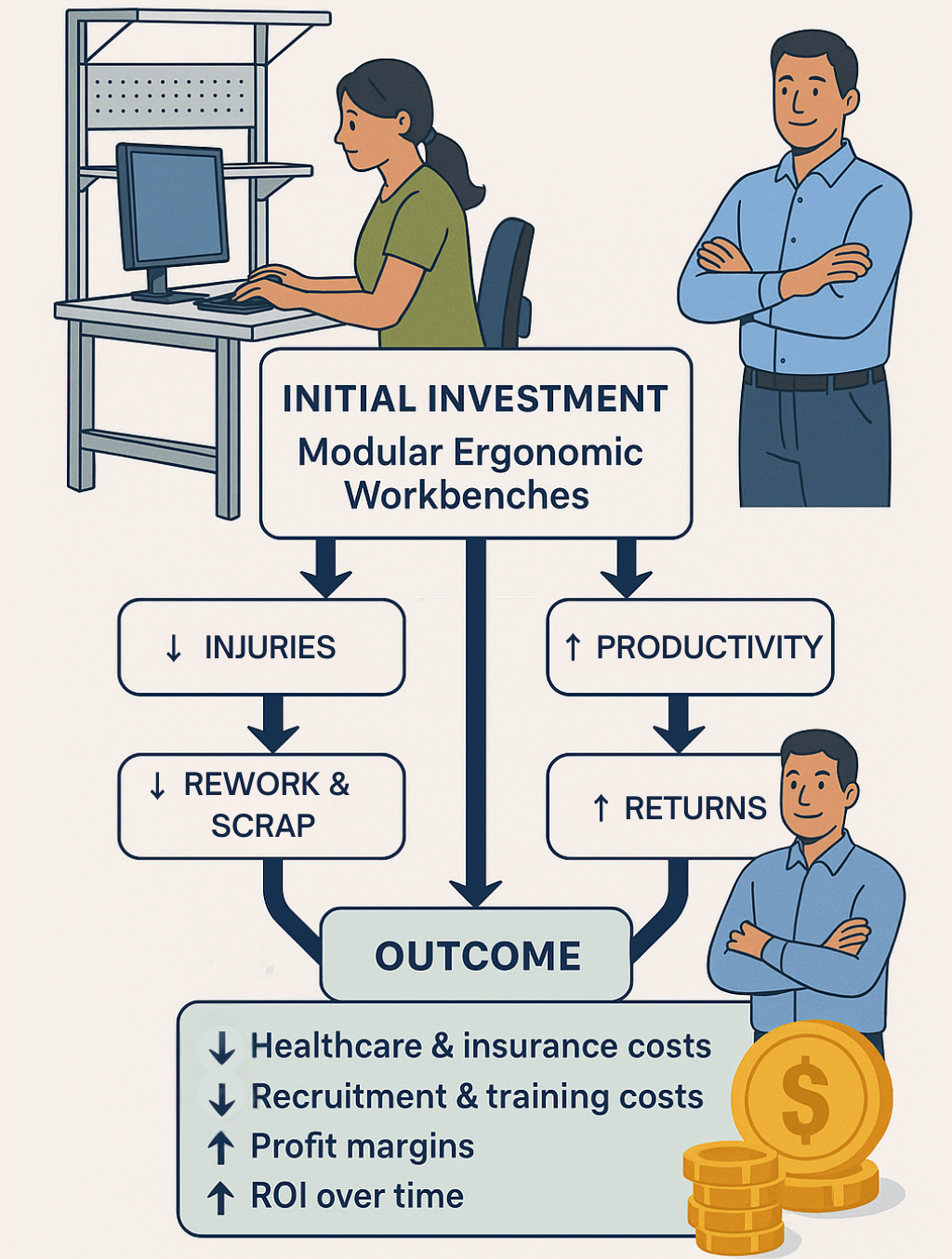

6. Long-Term Cost Savings

Investing in ergonomic and reconfigurable workbenches pays off across multiple dimensions. Reduced injuries mean lower healthcare and insurance costs. Improved productivity and reduced rework result in higher throughput and profitability. Plus, happier, healthier employees are more likely to stay- lowering turnover and the ongoing cost of recruitment and training. Over time, the return on ergonomic investment becomes evident in both operational and financial performance.

Financial Benefits of Ergonomic Workstations:

↓ Healthcare & injury costs

↓ Insurance premiums

↓ Absenteeism

↓ Recruitment & training costs

↑ Productivity & throughput

↑ Retention & morale

↑ Operational ROI

“Every ₹1 invested in ergonomics returns ₹2 to ₹6 in cost savings.”

— International Ergonomics Association

Benefits to Employers from Providing Ergonomic Workbenches

For employers, the return on ergonomic investment is tangible:

Higher throughput per operator

Fewer human errors due to fatigue

Reduced injury-related claims

Improved retention of skilled workers

Adaptability to evolving production needs

Whether you’re setting up a new production zone or upgrading an R&D lab, a modular ergonomic workstation provides lasting value.

Benefits to Employees from Ergonomic Workstations

For those using the workbench daily, the benefits are personal and immediate:

Reduced risk of repetitive stress injuries

More natural and comfortable posture

Greater control over tool access and task flow

Improved morale and job satisfaction

Lower fatigue and better focus

An ergonomic workbench is not just furniture- it’s a performance enhancer.

How Modular Design Supports Human Physical Demands

Traditional fixed benches fail to evolve with your workflow. In contrast, modular ergonomic workstations provide:

- Reconfiguration options for various tasks (e.g., testing, inspection, packaging)

- Quick add-on/removal of accessories like footrests, monitor arms, or lighting

- Adjustable heights and widths for individual comfort

- Task-oriented setup zones without needing new furniture every time

You can build once and repurpose many times-ideal for manufacturing labs, R&D environments, and dynamic production floors.

Ergonomic Workbench Essentials:

Key Features to Consider

Feature | Why It Matters |

Adjustable Height | Allows customization for standing or seated work |

Depth (600–900mm) | Ensures comfortable reach and visual clarity |

Worktop Material | Choose SS, ESD-safe, or HPL based on task demands |

Footrest (Fixed/Adjustable) | Reduces pressure on lower limbs |

Modular Accessories | Like bin holders, light arms, drawers, tool rails, etc. |

Load Capacity (100–150 kg udl) | For handling light-dut tasks, light-equipment setups |

Load Capacity (450–1000 kg udl) | Crucial for heavy-duty, heavy-equipment setups |

Reconfigurable Layout | Quickly adjust setup without replacing the entire unit |

Why Ergonomics Is the Future of Industrial Workspaces

The ergonomic workbench in manufacturing workspaces is no longer a luxury- it’s a necessity for lean, productive, and scalable operations.

Conclusion:

Choose a Workbench That Works for You

Choosing an ergonomic workbench isn’t just about physical comfort. It’s about increasing efficiency, supporting employee health, and creating a workplace that adapts to your workflow- not one that restricts it.

So the next time you plan a new lab or production line, ask:

“Does this workstation fit my people as well as it fits the task?”

If not, it’s time to explore modular ergonomic workstations- designed with human needs at the core.

Need Help Setting Up a Future-Ready Workspace?

Explore Furnisys’ range of modular ergonomic workbenches designed for manufacturing, R&D, electronics, and oil & gas sectors.

All purpose workbench series designed to functionally serve your basic workspace needs…

An adaptable workbench series designed for diverse technical environment…

An industrial grade workbench series designed to withstand rough work environments…

Our most flexible workstation — designed to adapt, expand, and reconfigure…

Our most flexible workstation — designed to adapt, expand, and reconfigure…

Experience efficient material handling with LINK Flow Racks—designed to streamline…