Workbench for Fabrication Area

Workbench for Material Testing

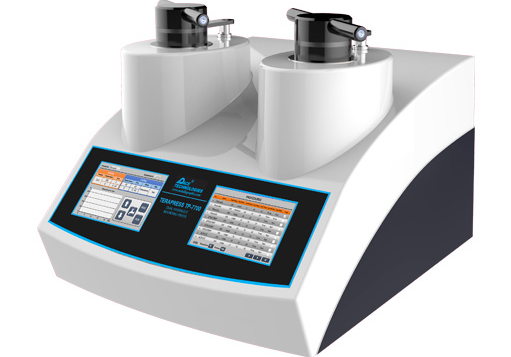

Integrated Platform for Hot Mount Press & Grinder

In the Oil & Gas industry, material reliability is non-negotiable. Every component used in drilling, exploration, and production tools must withstand harsh subsurface environments where extreme pressure, high temperature, and corrosive conditions are the norm. Before these materials can be trusted, they must undergo a rigorous evaluation process.

One of the most crucial steps in this process is sample preparation, where metals, elastomers, and other materials are carefully shaped and polished to reveal their mechanical and microstructural properties.

Why the Fabrication Area Matters

In any advanced R&D lab, the fabrication area is the backbone of accurate testing. Here, technicians prepare uniform cross-sectional specimens that later undergo microscopic analysis, hardness checks, and structural evaluations.

In this zone, two machines play a central role:

Hot Mount Press

For embedding samples in a solid mold.

Grinder/Polisher

For producing a smooth, precise finish on the specimen surface.

Without a stable and efficient workbench for fabrication area, these critical machines cannot perform to their full potential.

The Challenge

The client needed a robust workbench solution to securely hold both the Hot Mount Press and the Grinder/Polisher.

This workstation had to:

Provide ergonomic comfort, ensuring the bench was at the right height for technicians handling repetitive tasks.

Withstand mechanical vibrations, abrasive dust, and thermal cycles.

Enable smooth, fatigue-free operation so that each sample was prepared with precision and consistency.

The demand was clear, the workstation had to balance strength, stability, and ergonomics while keeping the workflow uninterrupted.

Furnisys Solution:

Heavy-Duty Stainless Steel Workbench

Furnisys responded with a dedicated, heavy-duty stainless steel workbench tailored to the fabrication area’s requirements. This workstation was not just a surface, but a carefully designed platform that directly supported the sample preparation workflow.

Stainless Steel Worktop

The SS worktop provided a flat, resilient surface for mounting the Hot Mount Press and Grinder/Polisher. Its thermal resistance ensured it could handle the high heat generated during pressing cycles, while its structural rigidity absorbed machine vibrations. This combination guaranteed that both the equipment and the prepared samples remained stable and accurate during operation.

Organized Storage for Tools & Consumables

Organized Storage for Tools & Consumables

Efficiency in the lab is not just about machines, it is also about organization. The base cabinets beneath the worktop offered dedicated storage for:

Mounting powders and polishing pads

Cleaning agents and safety gloves

Maintenance tools and spare consumables

By keeping everything within easy reach, technicians could reduce setup time and maintain a clean, clutter-free workspace. This streamlined approach made repetitive tasks easier and improved overall productivity.

A Stable Foundation for Sample Preparation

Consistent sample preparation

Reduced operator fatigue

Reliable results in downstream testing

The integration of durability, storage, and operator comfort made the workstation a cornerstone for accurate and efficient lab operations.

Why Furnisys Workbenches Stand Out

Choosing the right workbench for fabrication area is not about aesthetics alone, it is about ensuring reliability, safety, and workflow efficiency. Furnisys solutions are built to:

Withstand harsh lab environments

Improve ergonomic comfort for operators

Provide smart storage and organization

Deliver long-term stability for critical machines

By focusing on these essentials, Furnisys enables labs in the Oil & Gas sector to achieve precision and dependability in every stage of testing.

Conclusion:

The fabrication area workbench plays a defining role in material testing and quality assurance. For labs where precision cannot be compromised, Furnisys delivers solutions that combine strength, organization, and operator comfort in one integrated platform.