All Furnisys products are manufactured in-house in one integrated facility in Navi Mumbai, covering over 20,000 sq.ft. Our full control over production enables us to maintain high quality, take on projects of all sizes, and offer fast lead times with competitive pricing.

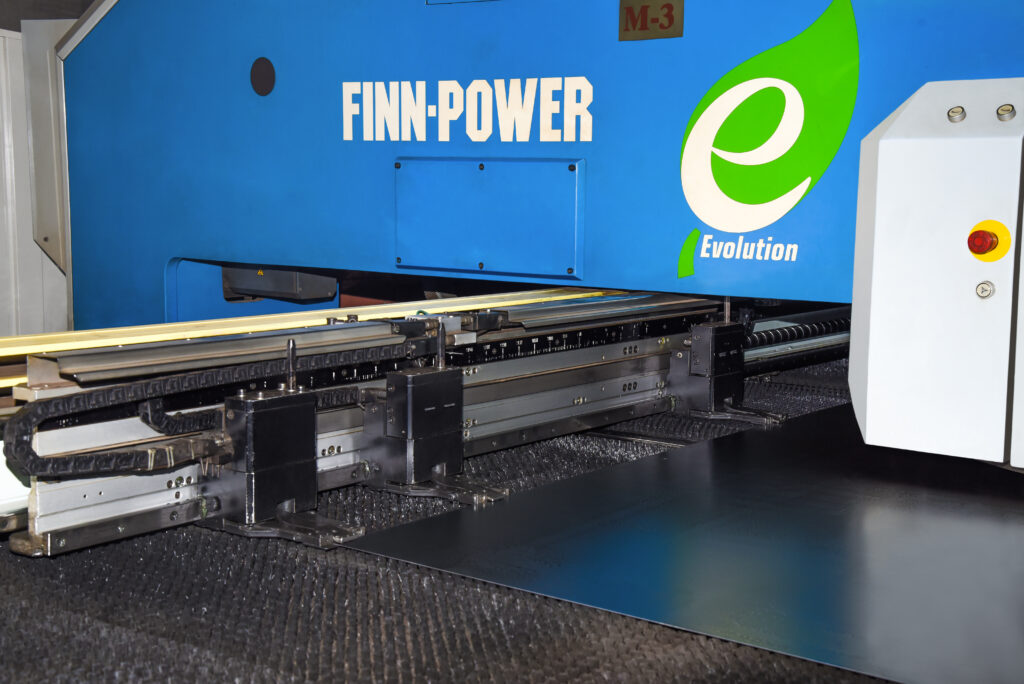

High-quality mild steel sheets are accurately cut using turret punching and shearing machines. Each component is sized as per design to minimize material wastage and ensure consistency across modular units like workbenches, cabinets, and trolleys.

CNC turret punching machines create precise patterns for mounting holes and functional cutouts on various parts. These features are designed to accommodate accessories and fixtures essential to the modular nature of Furnisys systems.

Using CNC press brake machines, components are bent to achieve clean lines and uniform angles. This process is critical in forming ergonomically structured frames, drawers, and supports that align with Furnisys’s system configurations.

Although most products are knock-down by design, specific load-bearing or structural components are CO₂ or spot welded to ensure strength and long-term stability. This selective welding approach supports both modular flexibility and structural integrity.

All metal parts undergo a 12-tank chemical pre-treatment process involving zinc or iron phosphating. This multi-stage cleaning removes contaminants, enhances corrosion resistance, and prepares surfaces for optimal powder paint adhesion.

Components are uniformly coated using electrostatic powder coating guns and cured in high-temperature ovens. This results in a durable, chip-resistant finish that meets industrial standards for both performance and appearance.

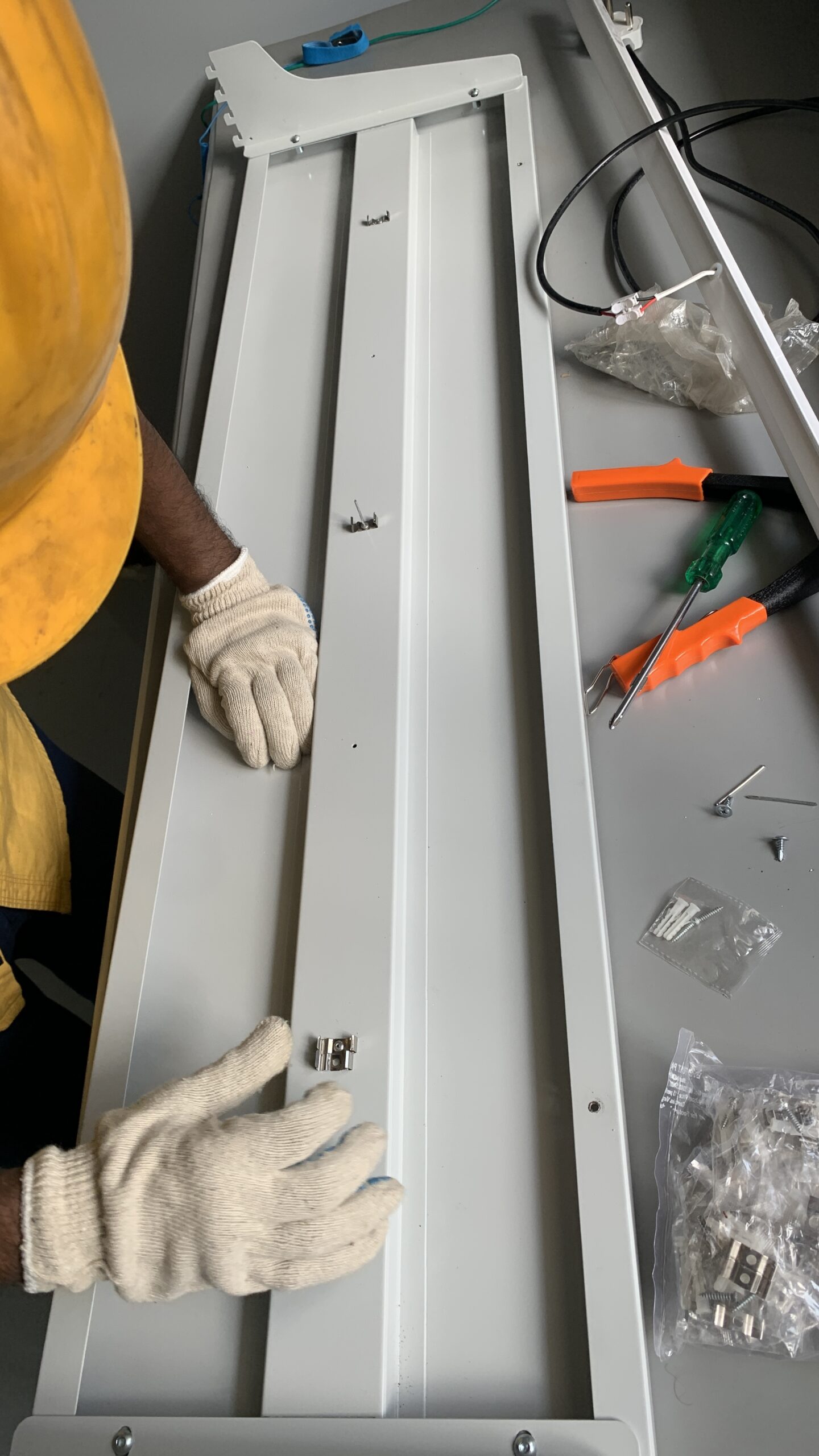

Post-coating, parts such as frames, panels, and drawers are brought together in a controlled assembly zone. Using fixtures, fasteners, and jigs, our team ensures that each system is aligned and fully compatible with its intended configuration.

Every assembled unit is inspected for visual finish, alignment, and functional quality. Once approved, products are securely packed with protective materials to ensure all modular components arrive in perfect condition, ready for installation.

Furnisys systems are designed for easy on-site assembly with clear manuals provided for each unit. For additional support, remote video assistance is available, and professional installation services can be arranged on request for seamless setup.

©2026 Furnisys, All rights reserved.